Project: Aluminum Manifold

Project Overview: FC&A assumed a pivotal role in the project, focusing on the precision machining and expert fabrication of an aluminum manifold for our client.

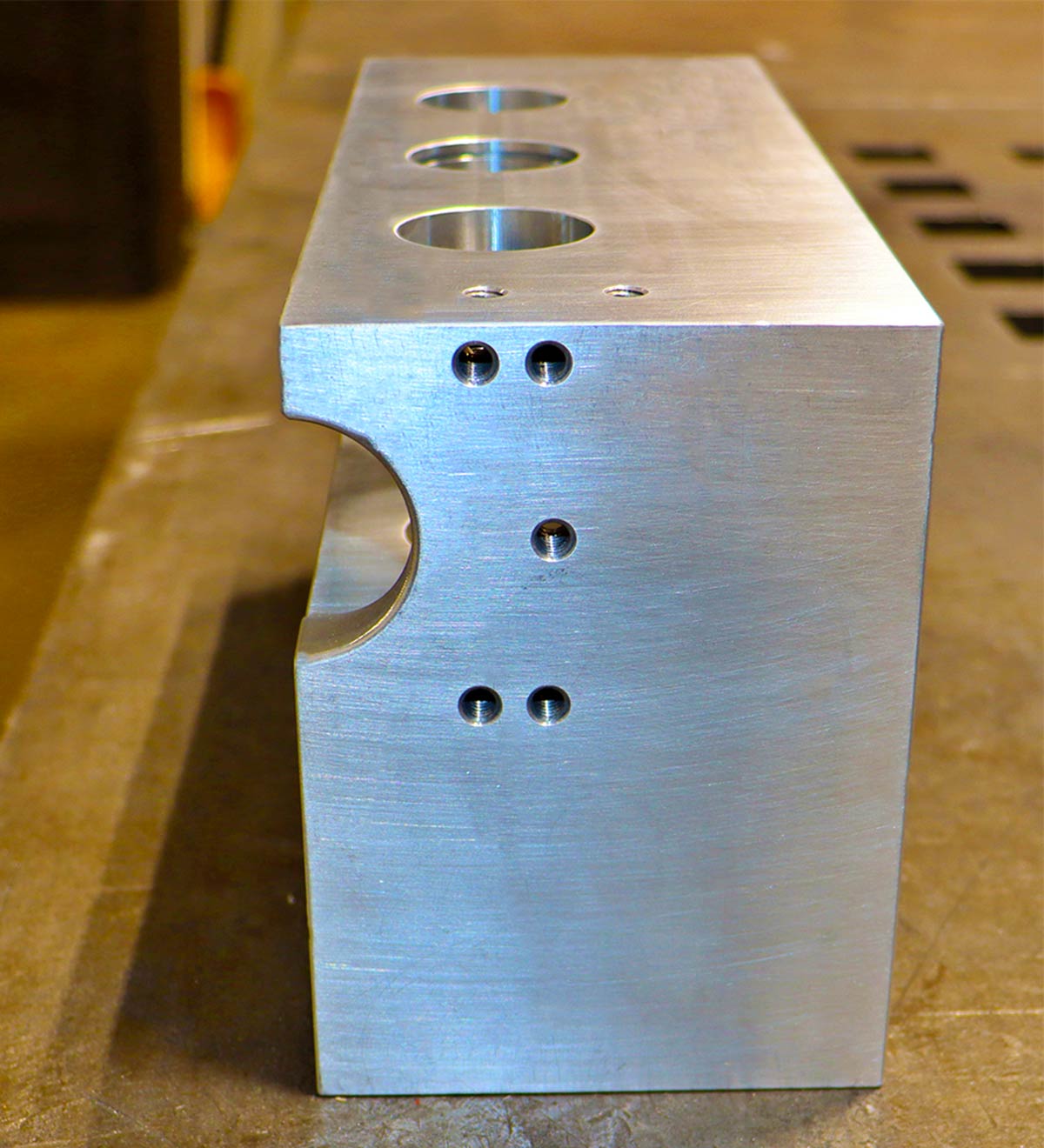

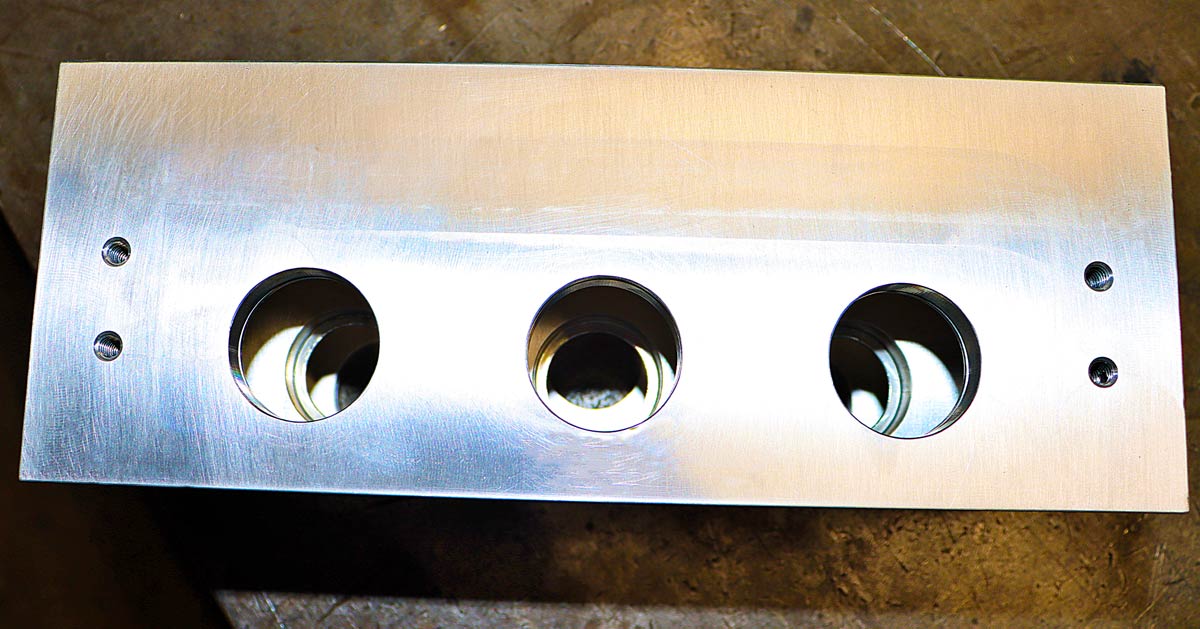

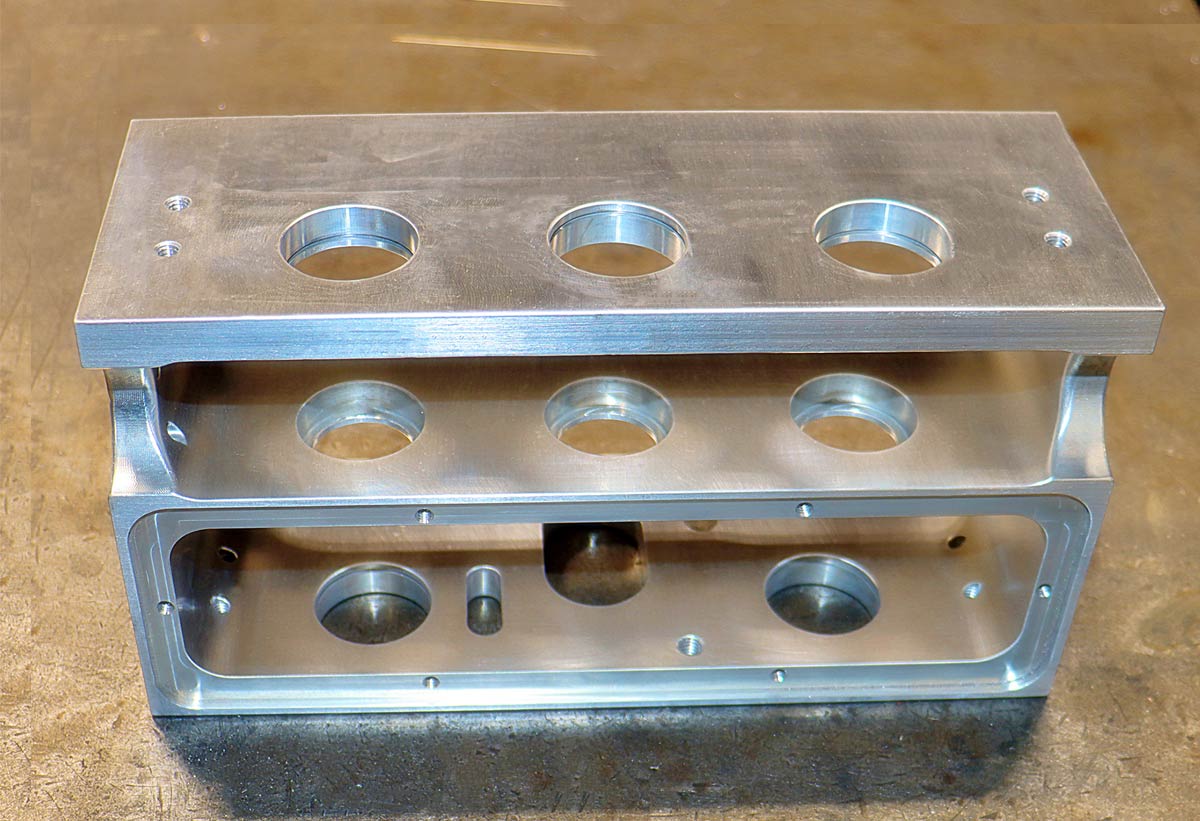

Machining Expertise: The project commenced with a specialized machining phase, where FC&A’s skilled machinists leveraged advanced techniques and machinery to carve out the intricate details of the aluminum manifold. Precision machining was paramount to ensure that the final component met the exact specifications required for optimal performance within the client’s operations.

Craftsmanship: Following the machining phase, FC&A seamlessly transitioned into the fabrication stage. Our experienced fabricators meticulously assembled the machined components, emphasizing structural integrity and functionality.

Partnership: Collaborating closely with the client, FC&A’s approach was strategic and tailored to the specific needs of the project. The partnership was marked by effective communication and alignment of efforts to achieve the desired outcome. This collaborative synergy underscored our commitment to delivering solutions that align seamlessly with our client’s objectives.

Outcome: The culmination of FC&A’s efforts resulted in the successful delivery of a precision-crafted aluminum manifold. The final component showcased the intersection of advanced machining techniques and expert fabrication, meeting the project’s specifications and contributing to the operational efficiency of the client’s systems.