CNC Machining

Our state-of-the-art CNC machining processes are designed to elevate your projects to new heights of accuracy and efficiency.

Capabilities

Our CNC machining capabilities are:

- Mill 32” W x 84” L x 24” H

- Lathe – Bar 3” Max OD – Tube 13” Max OD x 28” Lg

Milling Excellence:

Equipped with advanced CNC milling machines, we can precisely shape and contour a variety of materials, delivering intricate designs and detailed components with exceptional accuracy. From prototypes to production runs, our milling capabilities are geared to exceed your expectations.

Lathe Turning Expertise:

Our CNC lathe turning capabilities enable us to produce cylindrical and symmetrical components with unparalleled precision. Whether you require intricate parts or larger-scale components, our CNC lathes deliver consistent results, meeting the highest standards of quality.

Drill Press Operations:

Efficient and accurate hole drilling is crucial in many applications. Our CNC drill press operations ensure precise hole placement and dimensions, maintaining the integrity of your designs and meeting stringent quality standards.

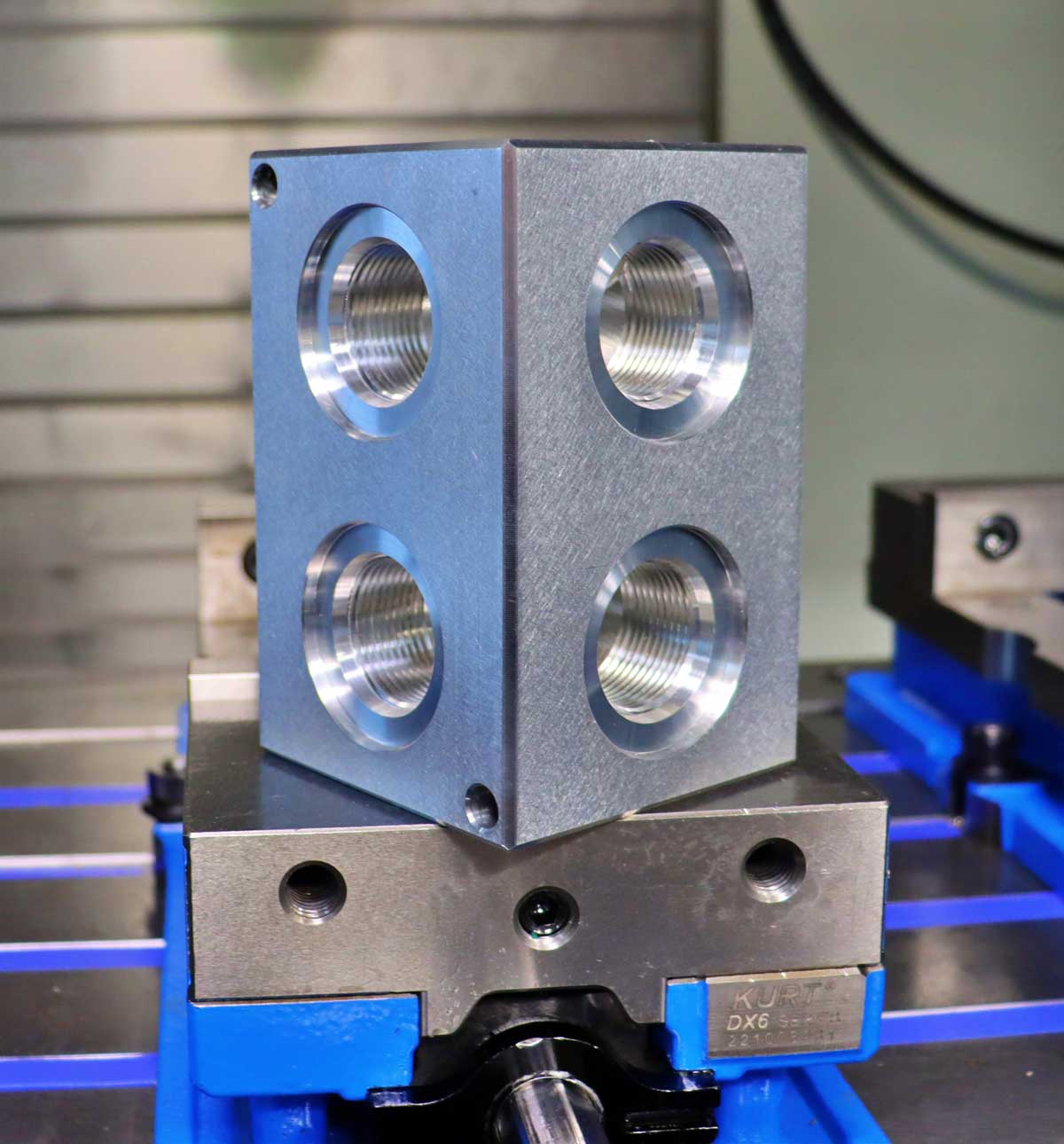

Tapping Table Proficiency:

Threaded components are a vital part of many projects. With our CNC tapping table, we can create precise threads in various materials, contributing to the overall functionality and reliability of your products.

Quality Assurance:

At FC&A, we prioritize quality in every step of the CNC machining process. Rigorous checks and inspections ensure that the final components meet or exceed industry standards, providing you with the confidence that your projects will be executed with excellence.

Whether you have intricate prototypes or large-scale production needs, FC&A Metal Fabrication’s CNC machining capabilities are engineered to bring your designs to life with precision and efficiency.